- HOME

- Business

- EIC Engineering

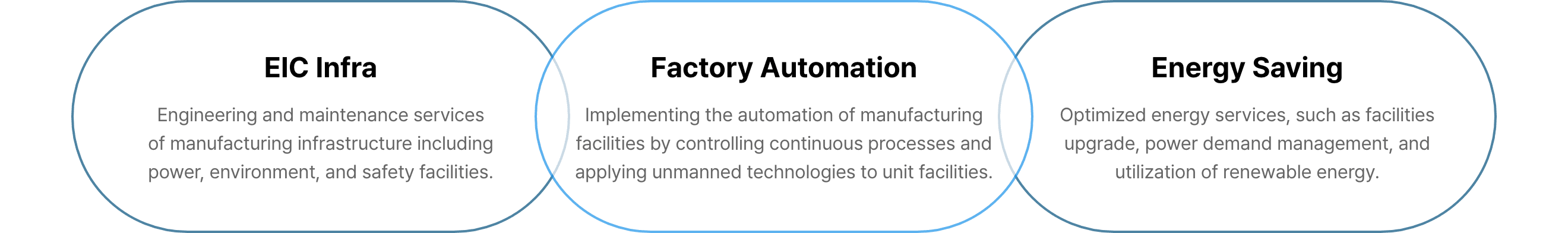

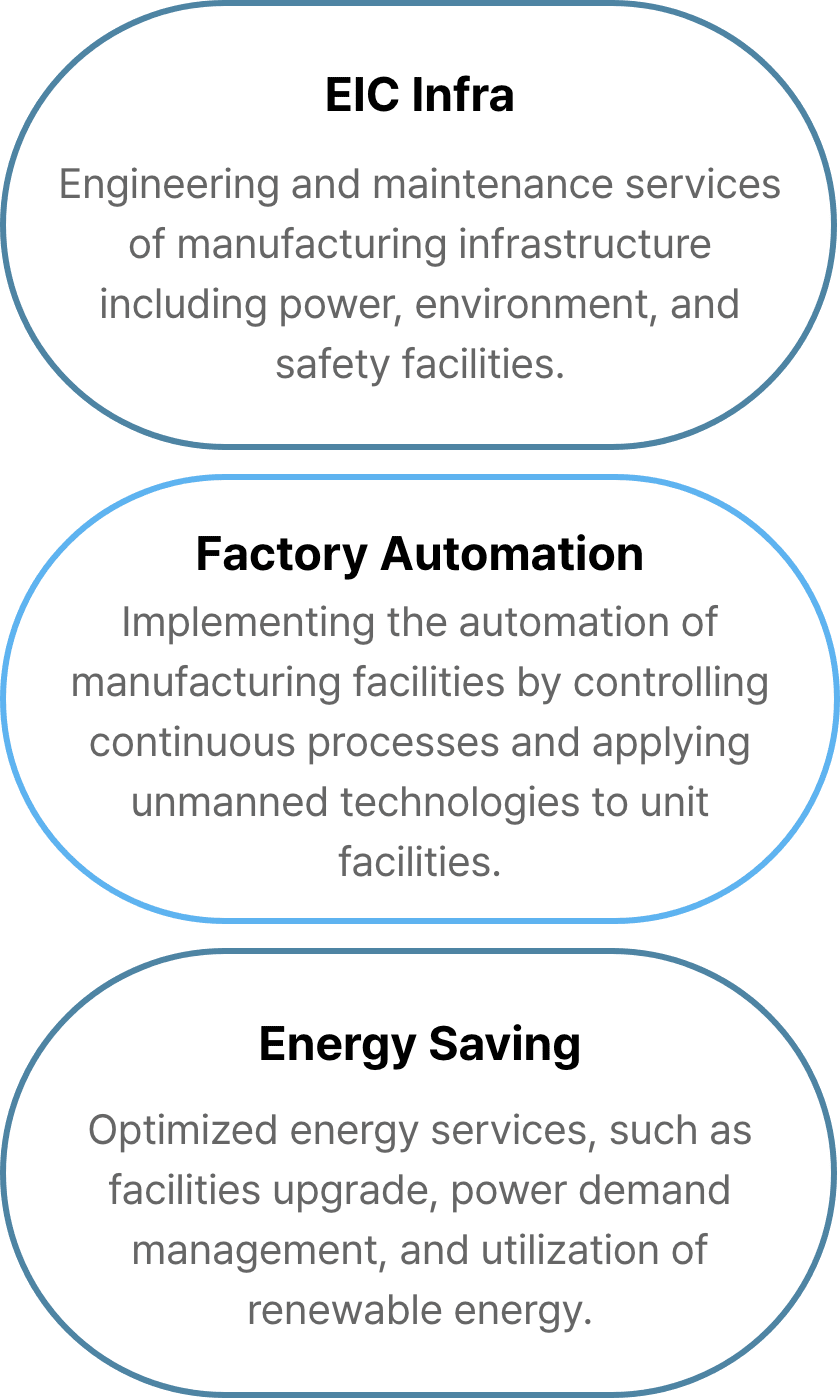

EIC Engineering

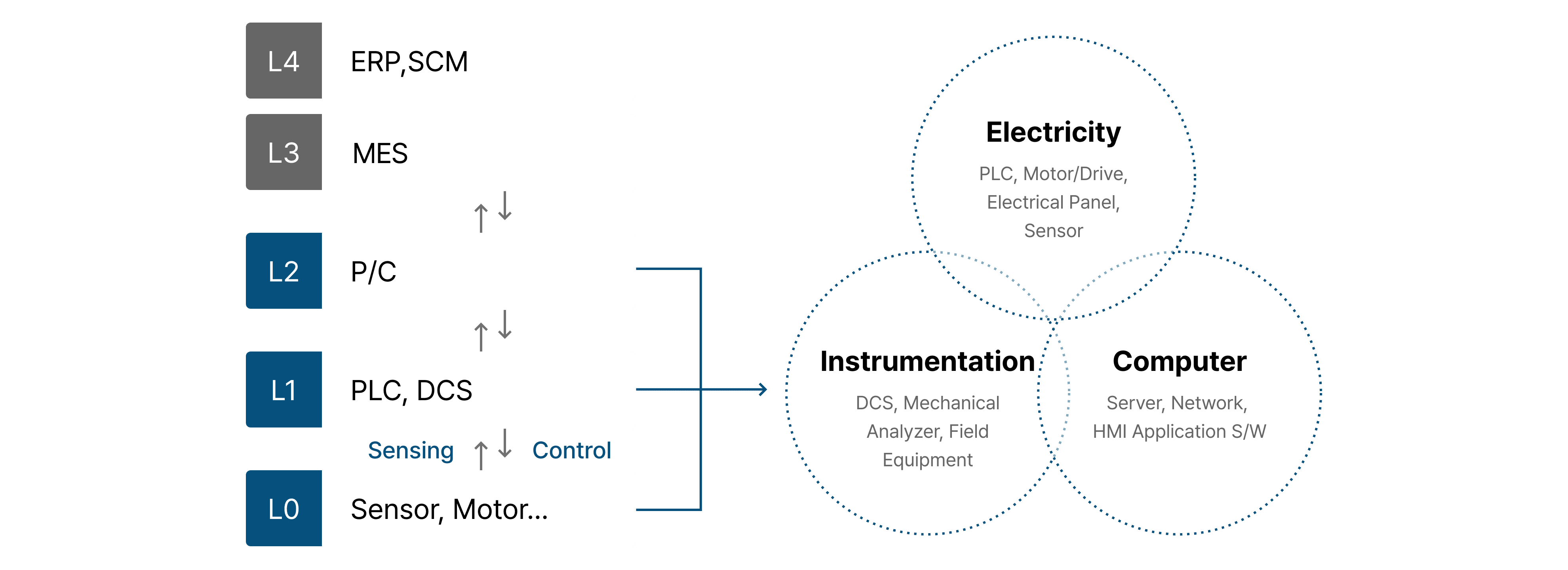

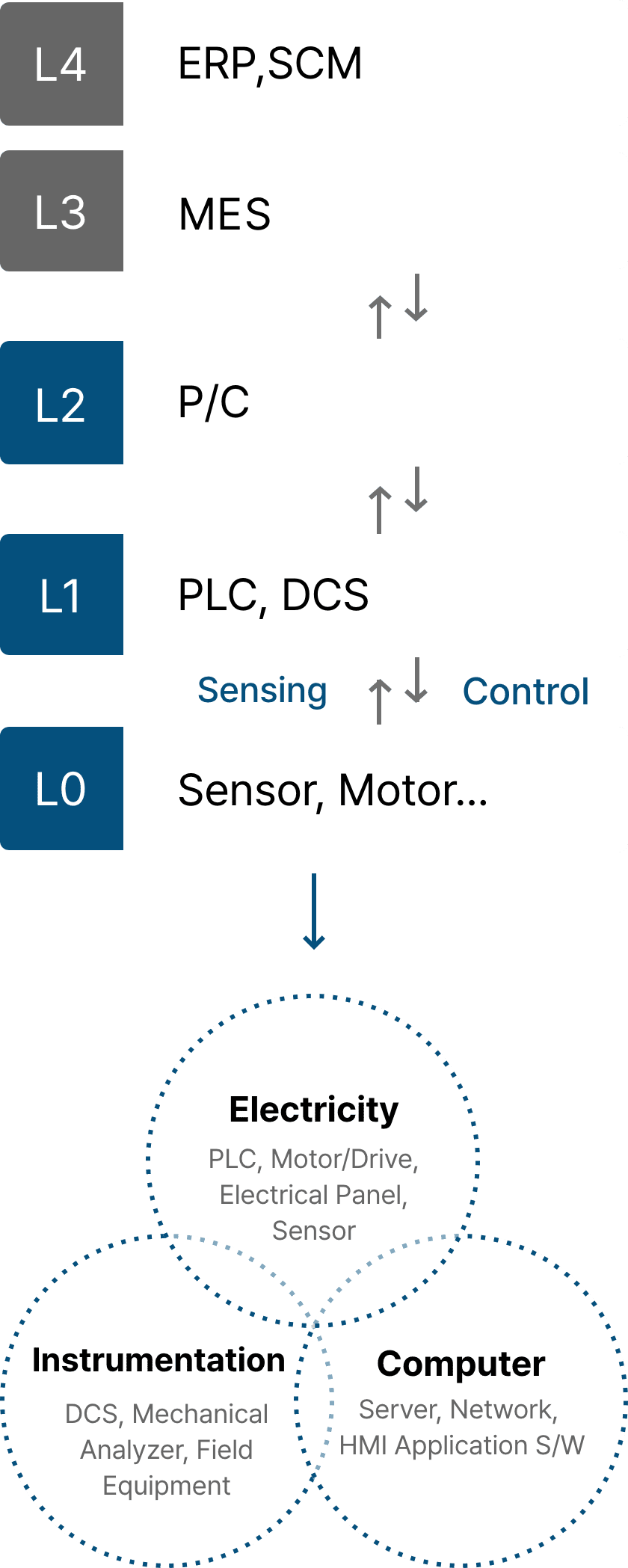

POSCO DX leads smart control centered on factory automation while providing the best process automation solution by combining electricity, computers, instrumentation, and more.

Factory Automation

POSCO DX boasts of 40+ years’ experiences and capabilities in the provision of total EPC(Engineering Procurement Construction) service in steel production and power generation plants as well as EIC engineering services to implement unmanned controls for unit facilities of production plants.

Automation of continuous processes

Establishing a process control system utilizing measurement sensor, PLC, and computer systems for the automation of manufacturing facilities.

Integrated system for the automation and efficient control of on-site facilities by utilizing diverse applications for controlling manufacturing systems and related processes.

Automation of unit facilities

System of unmanned technologies for cranes (in yards and warehouses)

Complete automation and application of unmanned technologies of cranes with data and know-how in the L1(PLC) ~ L3(MES) fields.

- Our Technology

-

- Designing work schedules

- Cabin HMI control technology

- Correct position/Anti-Sway control technology

- Product loading/unloading control technology

- Product and grip recognition control technology

- Inter-crane interference control technology

- Ground obstacle evasion and control technology

- Collision prevention and control technology

Warehouse automation (products and materials)

Application of automation for all processes from location/facilities control and warehouse-storage-shipping by utilizing L0 (sensor) ~ L3 (MES) technologies. We also have technologies to optimize logistics processes and loading methods based on MES including warehousing and shipping sequence per product.

Automation of material transportation (iron ore and coal)

- Automation of stacker and reclaimer in materials yard and cokes moving machine.

- Main technologies: Correct position, synchronization of facilities, material input and collision prevention, Wireless communication and video.

- Cases: Material yard of POSCO, Stacker/Reclaimer for South-East/Midland/East-West Power companies

EIC Infrastructure Service

We provide engineering services to establish and operate an infrastructure control system in support of the operation of major production facilities.

Power facilities

- Power facilities engineering for substations and factories supplying power from external grid to on-site facilities.

- Remote integrated surveillance system for transformers and online power facilities surveillance system engineering.

-

154KV Transformation Eng’(GIS, TR, Cable)

-

Power System Eng’(VCB, TR, Protection)

-

Integrated Energy Monitoring System(UCC)

-

On-line Power System Monitoring System(전력안정화)

Safety/Environment

- Safety management services utilizing safety equipment such as firefighting facilities and CCTV.

- Environmental facilities engineering services such as TMS, dust collector, and water process.

-

Safety

- Smart Safety Equipment : CCTV, safety vests, etc.

- Safety and Fire Surveillance Systems : Gas leaks, fire equipment, etc.

- Facility Safety Monitoring : Belt conveyor defects, etc.

-

Environment

- Smokestack Tele-Monitoring System (TMS) : fine dust, air, etc.

- Dust Collection/Water Treatment/Utility Control Systems

- Purification facilities (SCR, desulfurization/denitrification)

Maintenance

- Dedicated maintenance of power instrumentation and hardware and software of process computers / Dedicated maintenance of steel EIC

- Maintenance tasks including establishment of a maintenance plan, error prevention, and procurement for the entire process line PC operation service

- Support for hardware (server and HMI) and application software for process computers, AI system, and DAQ in charge of Level 2 controls

Energy Saving

POSCO DX provides the complete services needed for using energy efficiently from energy demand/supply optimization to consumption optimization.

Demand Response

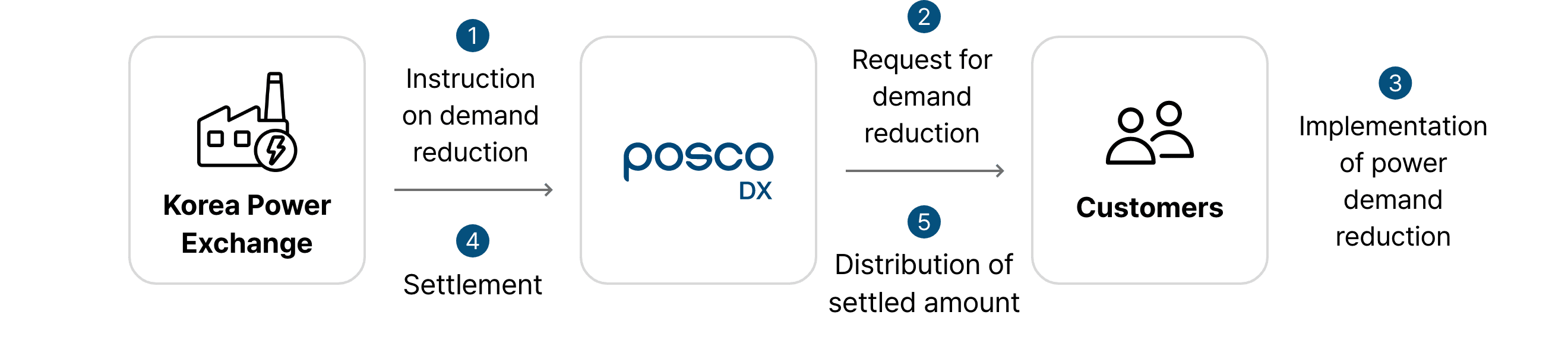

As a demand response business operator, POSCO DX calculates the optimum contract capacity by analyzing the characteristics of the customer’s place of business and proposes an optimum demand reduction strategy to ensure that customers can get maximum compensation at the time of actual reduction by the request of the Korea Power Exchange. Customers can save on energy costs by reducing power and generate additional profits by participating in the project.

Power Management

By attaching sensors to all pieces of equipment and based on the Factory Energy Management System, which is POSCO DX’s industrial solution for the efficient use of energy, energy costs can be saved by operating the facility efficiently through the analysis of the entire process including purchase, use, and management of energy and by using automated system control.

Improving energy management and operational efficiency with a real-time operator monitoring system.