- HOME

- Business

- Smart Logistics

Smart Logistics

POSCO DX, based on the know-how acquired by installation and operation experience of baggage handling system at Incheon International Airport, now provides total logistics automation services to the manufacturing and logistics industries.

Total Solution Provider

“Providing total logistics services with consulting & engineering, facility building, and operation and maintenance.”

-

Consulting & engineering

-

Facility building

-

Operation & maintenance

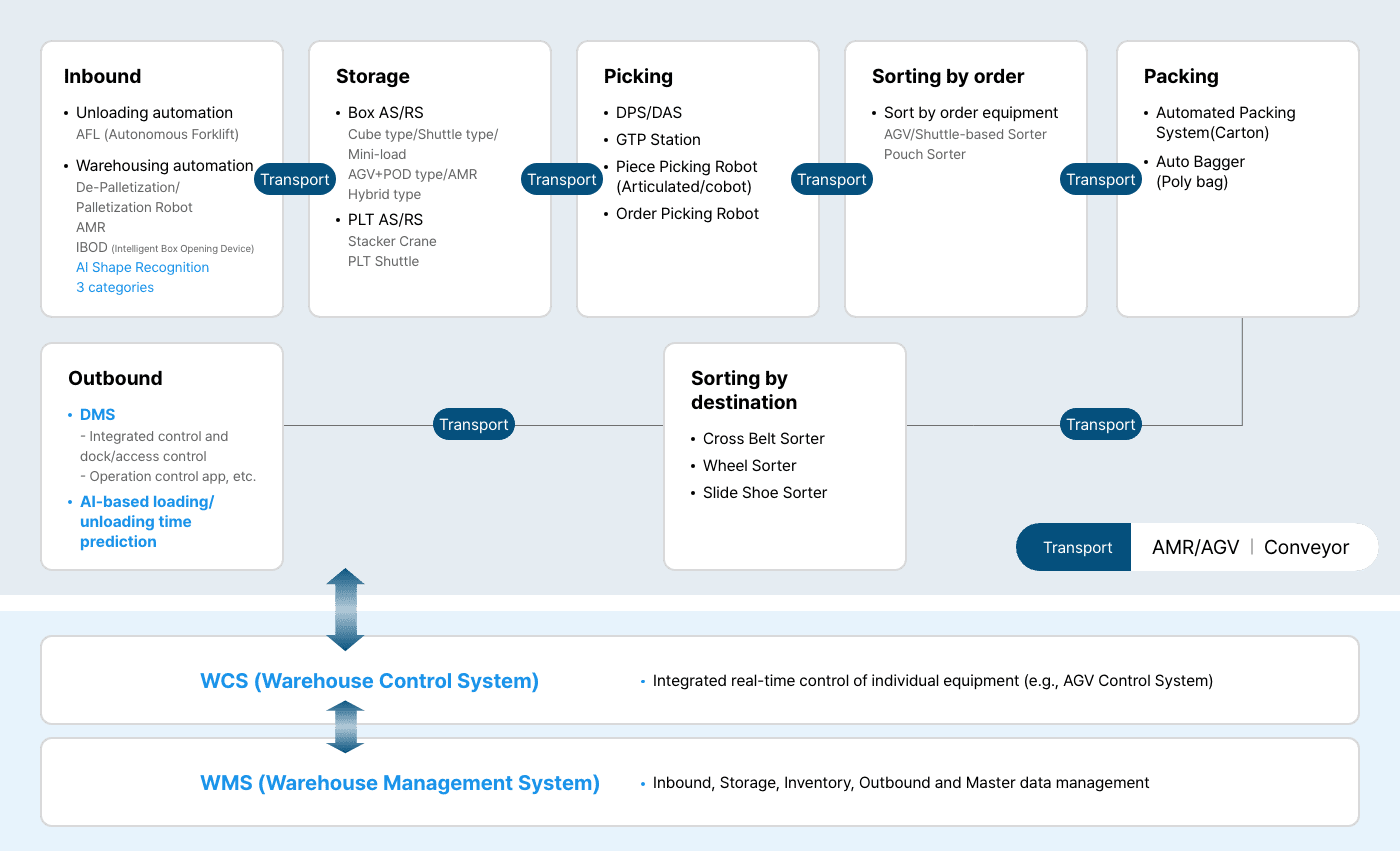

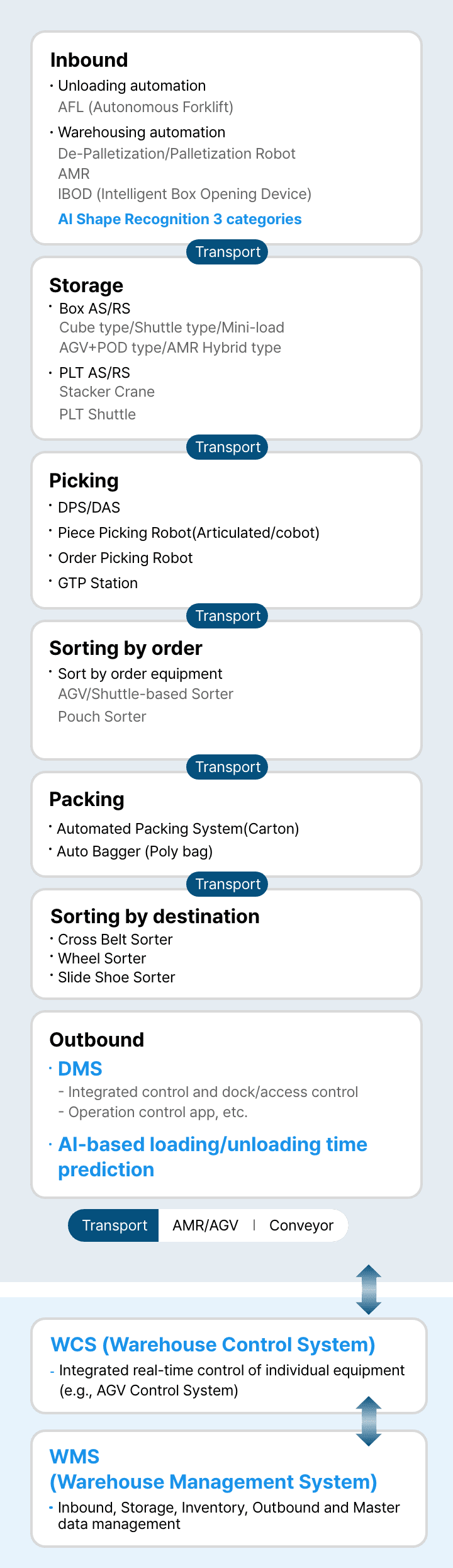

Logistics Automation

We provide total logistics automation services such as consulting / design / installation / maintenance / operation, to the logistics and manufacturing industries, in addition to the airport baggage handling project. Our reference covers 24x365 automatically-controlled plants, unmanned material warehouses, some of the largest logistics centers in Korea, and global top-class airports.

To Logistics Industry

We provide the consulting, design, installation and integration of automation equipment, and operation outsourcing services to the logistics industry. Layout design, mechanical engineering, PLC control and IT solution implementation shall be provided with our own technology. Innovative automation facilities and solutions, which can enhance the productivity and competitiveness of our customers, shall also be provided by our global partners.

Logistics Center

Differentiators and Competitiveness

- POSCO DX, as a very competent system integrator, will satisfy customer needs of operational efficiency and stability.

- POSCO DX builds systems efficiently through proper combination of innovative equipment procured from strategic partners and in-house IT & engineering technology.

- POSCO DX customizes automation solutions for large logistics centers (parcel delivery/e-commerce), medium/small logistics centers (apparel, bio-pharmaceutical, etc.), manufacturing/material warehouses, and more, respectively.

To Manufacturing Industry

Fulfillment Center for Manufacturing Industry

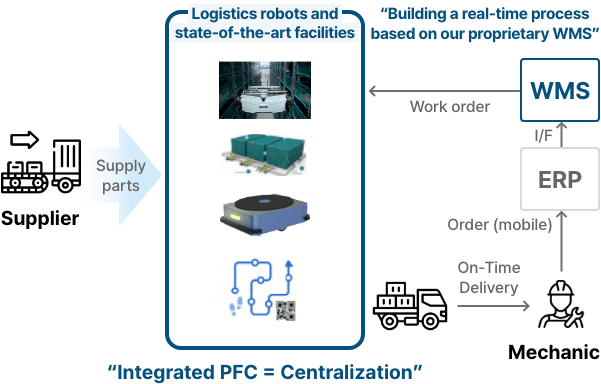

Fulfillment center concept of e-commerce is recently driving innovation in the manufacturing industry, along with the advanced logistics automation technology such as AGV/AMR, automated 3 dimensional storages, GTP, and hybrid AS/RS. POSCO Fulfillment Center (PFC) for maintenance materials and parts, built by POSCO DX is a good example of this trend.

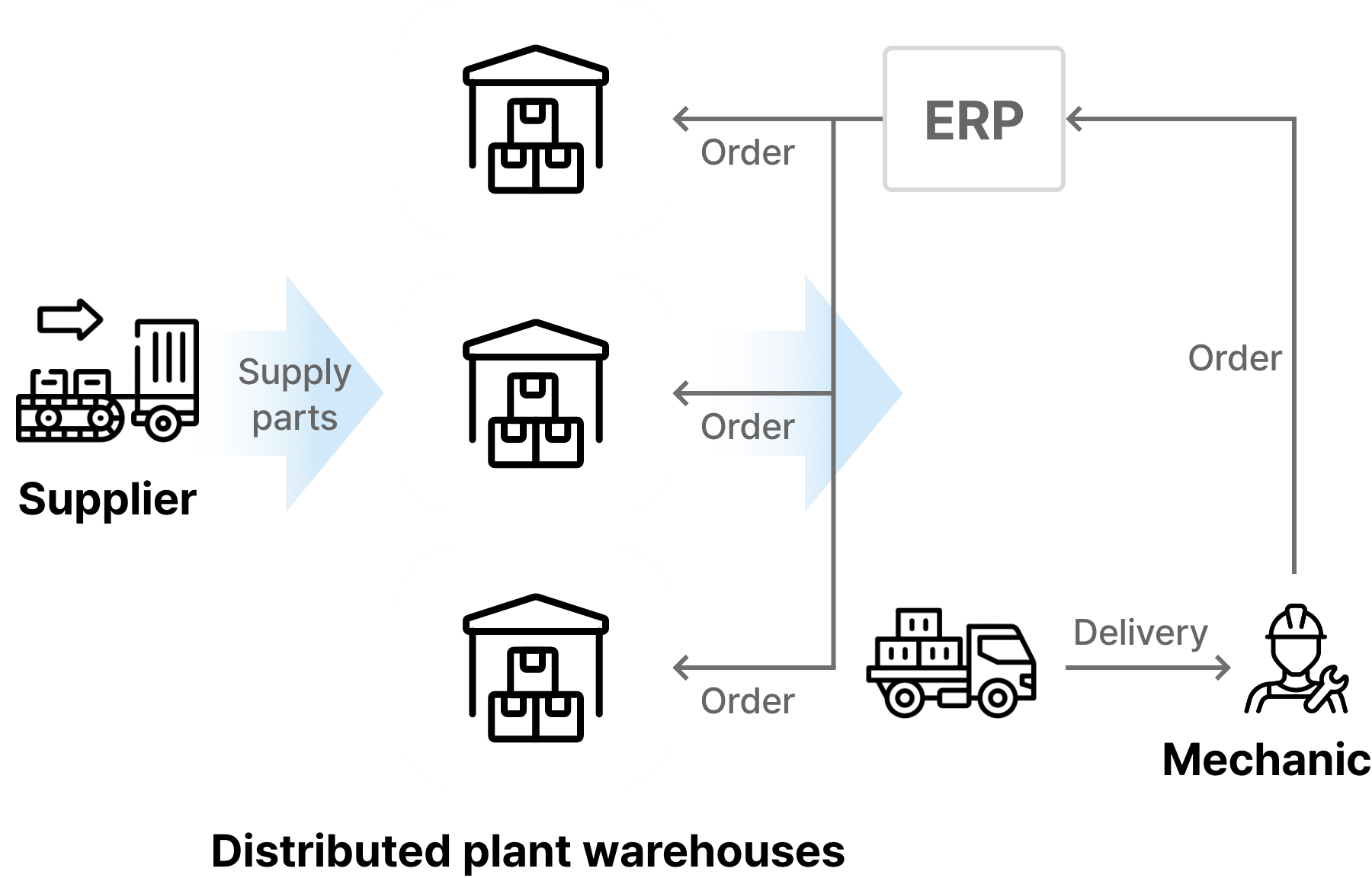

- Each warehouse is doing its own fulfillment, and overstocking risk exists due to buffer stocks of each warehouse

- Low inventory visibility

- Improved productivity in materials warehouses with automation in the PFC, which integrates existing warehouses.

- WMS enables real-time management of the ‘order > inbound > storage > outbound > delivery’ process and high inventory visibility.

※ We are gradually integrating over 300 materials warehouses distributed at many plants within POSCO Steelworks into a single fulfillment center.

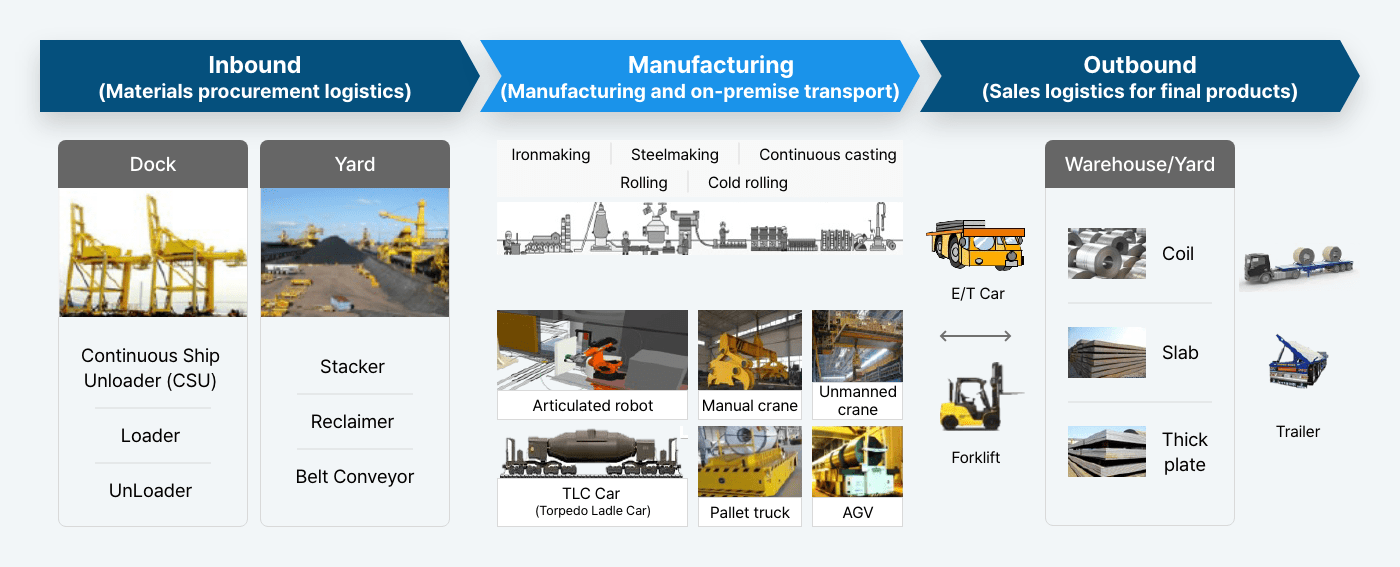

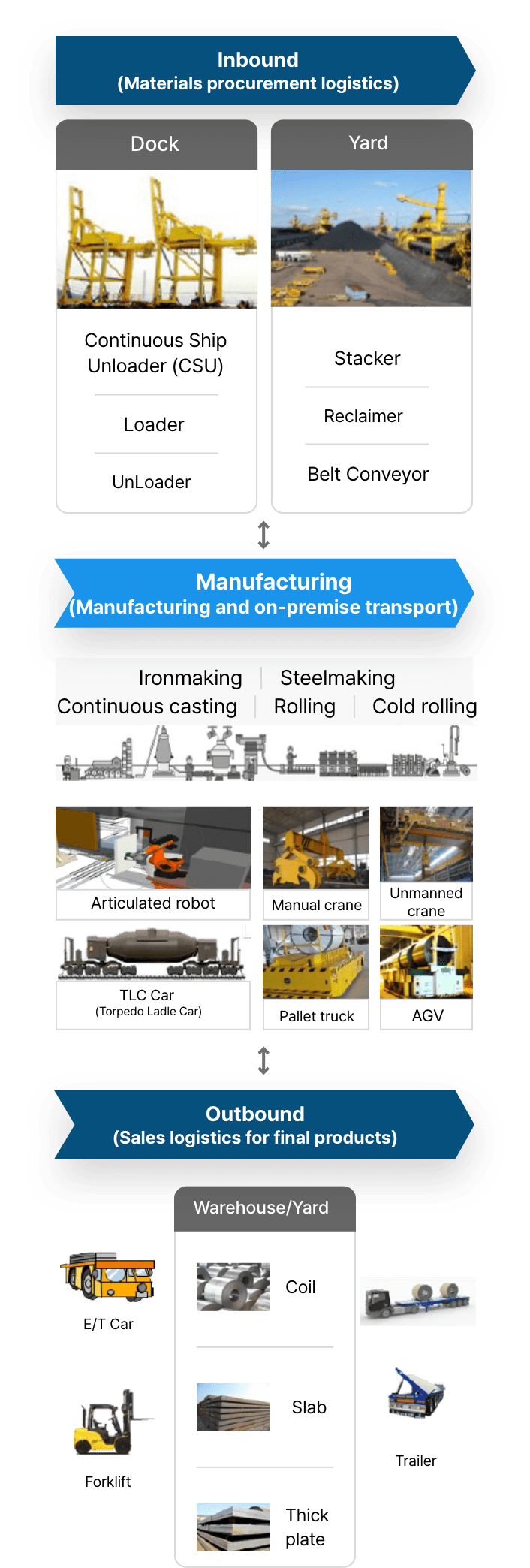

Logistics Automation/Intelligence for manufacturing industry

We integrate and apply digital technologies, such as AI, big data, digital twin, and robotics to the inbound, manufacturing & production, outbound processes of material / component / product manufacturing plants to maximize productivity.

Steel Mills

Major Projects and References

[Logistics Industry]

-

- Logistics automation at Hanjin Smart Mega Hub Terminal in Daejeon.

- Consulting on integrated FC automation facilities for CJ Logistics.

- Logistics automation at GS Retail Gunpo new logistics center.

- Installation of sorting system at DHL Logistics Center in Incheon.

- Logistics automation at Korea Post’s Incheon, Jeonju, and Jeju Mail Centers

[Manufacturing Industry]

-

- Construction of POSCO Fulfillment Center in Gwangyang Steelworks

- AS/RS based storage automation at ore lithium plants 1 and 2 of POSCO Pilbara Lithium Solution

- Phases 1 and 2 of Production and AS/RS based storage automation at POSCO Future M cathode materials plants

- Robot and AGV-based process automation at POSCO Future M refractory calcination plants

- AGV-based transportation automation at POSCO's electrical steel plates plant.

- AS/RS based storage automation at POSCO’s wire rods plant.

- AS/RS based storage automation at POSCO’s materials warehouses and sub-materials warehouses.

- AS/RS based storage automation at POSCO Future M smart refractory plant.

Partner companies

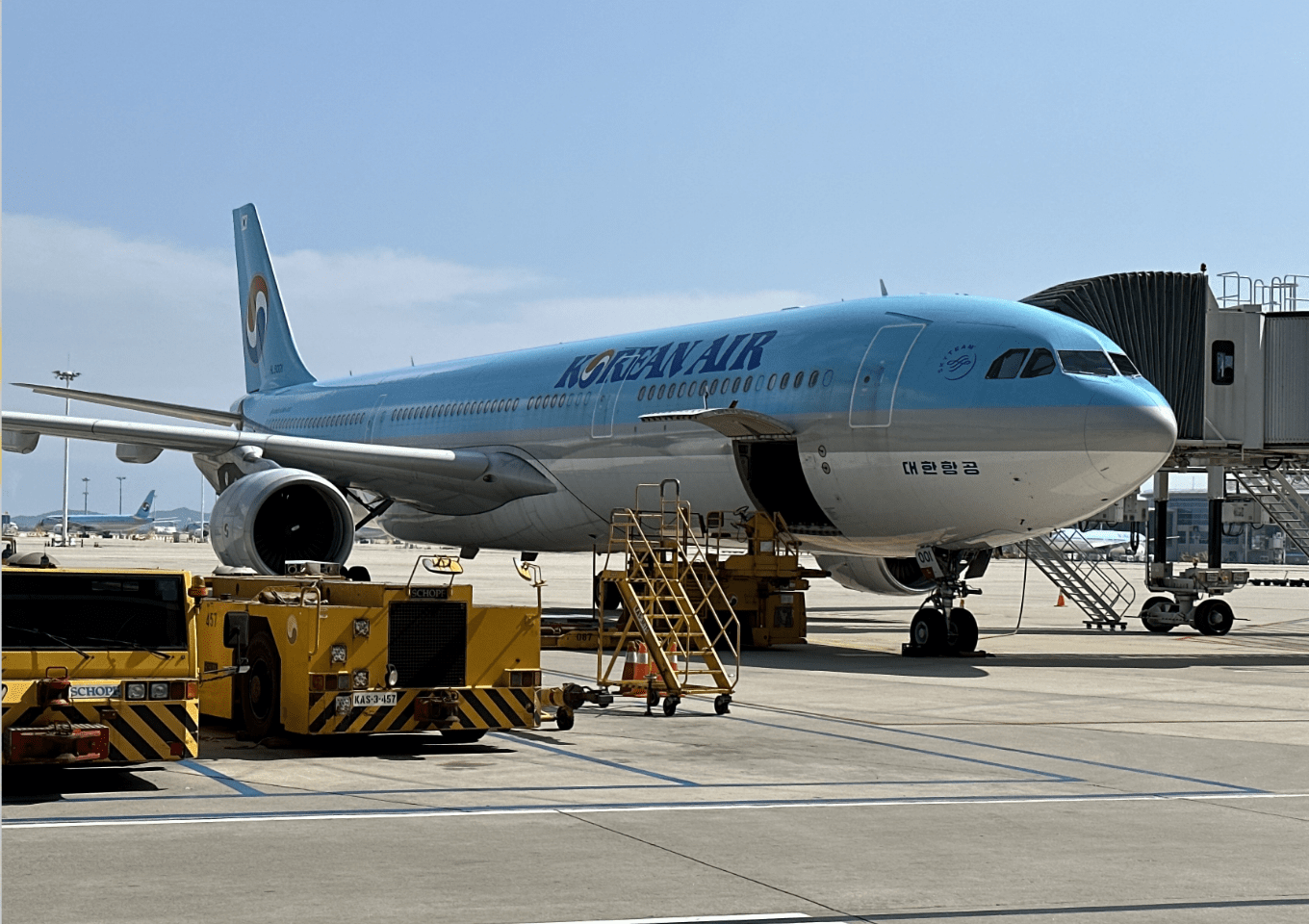

To Airport: BHS (Baggage Handling System)

Based on our experience in building and operating baggage handling systems at Incheon International Airport, we provide differentiated services in all areas of BHS, ranging from consulting, design, equipment/solution procurement, to the operation and maintenance service.

Key Features

The BHS is a system that transports checked baggage from the check-in counter to the designated airplane, and from the airplane to the baggage claim area. This system automatically transports, sorts, searches, stores baggage by reading tags attached to it. We have been building and operating the BHS and the relevant infrastructure at Incheon International Airport for 20 years, with an excellent performance (error rate is just 0.0002%), helping Incheon Airport become one of the best airports in the world for several consecutive years.

- Check-In: Baggage information is perfectly interfacing with airline/airport information systems.

- EBS (Early Bag Storage): Early check-in baggage are temporarily stored in EBS for further processing

- Make-up and unloading: A range of automated and semi-automated solutions is applied to optimize loading and unloading operations.

- Baggage carousels: Custom designed modular, low-noise carousels are provided to facilitate the operation at the baggage claim area.

Differentiators and Competitiveness

- POSCO DX has the know-how of world best BHS from Incheon International Airport experience.

- POSCO DX incorporates AI, big data, IoT, and other technologies into system management and operation to provide smart facility management, improved availability, and more efficient manpower operation.

- POSCO DX provides advanced technology through partnership with the world's largest global logistics solution companies.

Major Projects and References

- Construction of BHS at Incheon International Airport phase 4 (~ '24.10.).

- Construction of BHS at Incheon International Airport phase 1, 2, and 3 (T1, T2).

- Integrated (mechanical, electrical and control, computing system) operation and maintenance service to Incheon International Airport BHS Phase 1 and 2.

- Construction of BHS at Jeju International Airport.

- Building of baggage handling system for the Airport Railroad.

- Construction and operation consulting of BHS at Erbil Airport and Duhok Airport, Iraq.

Smart Integrated Logistics Platform

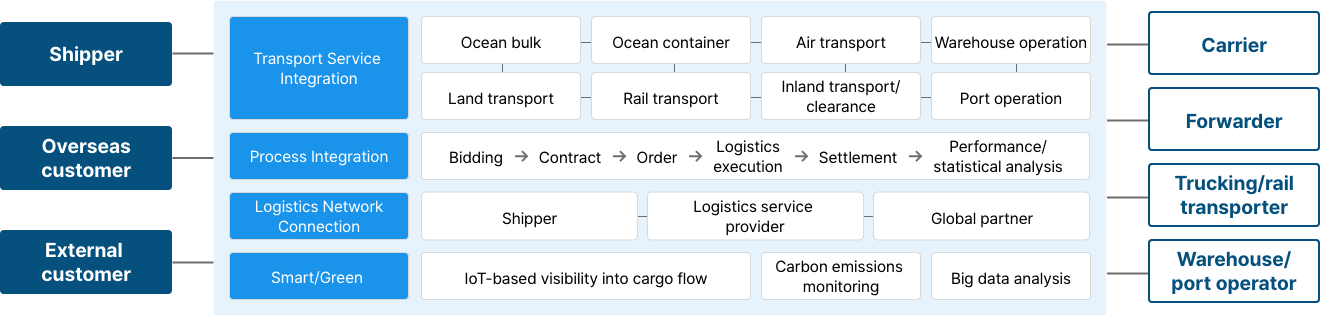

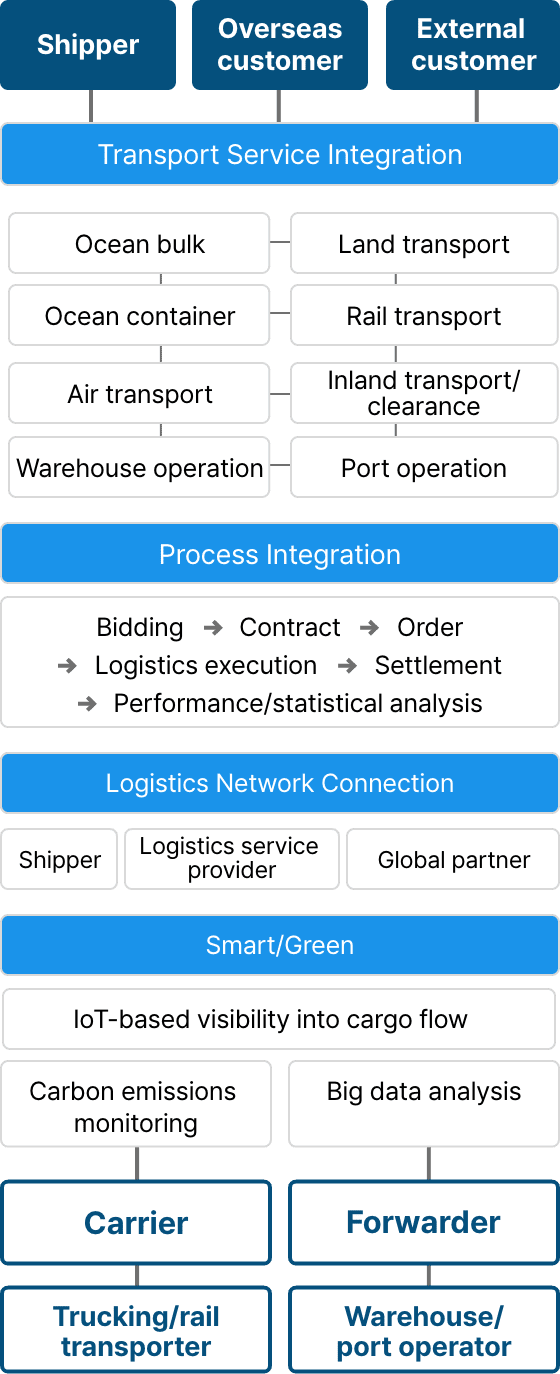

Smart Integrated Logistics Platform is an eco-friendly/intelligent logistics platform equipped with smart technology that integrates various transportation modes and logistics processes into a single point of contact and responds flexibly to future logistics business expansion.

Key Features

By integrating the seven major logistics services of ocean bulk, ocean container, air transport, road transport, rail transport, warehousing, and port stevedoring, we provide integrated management of cargo, data, and financial flow across the logistics network as well as one-stop logistics services from bidding and contracting to logistics execution and settlement.

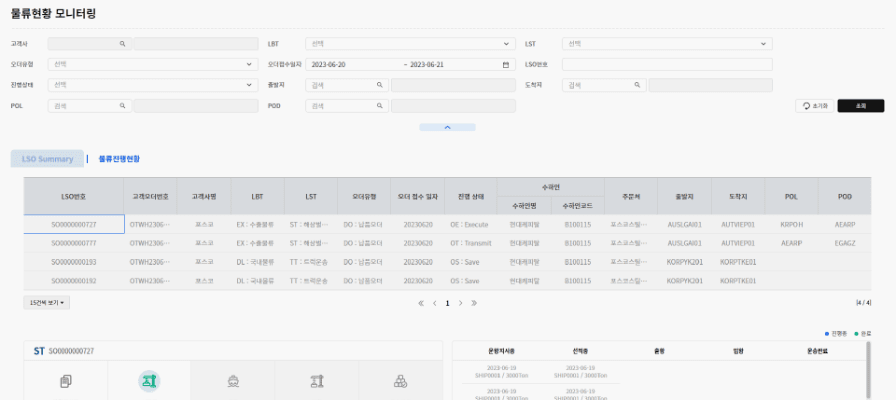

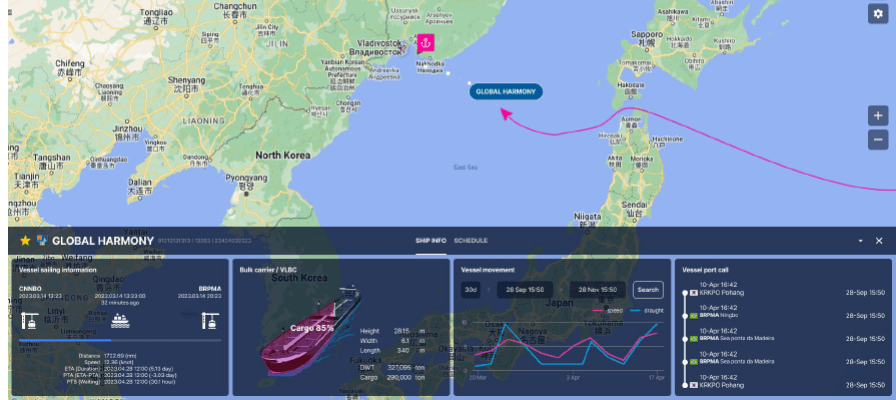

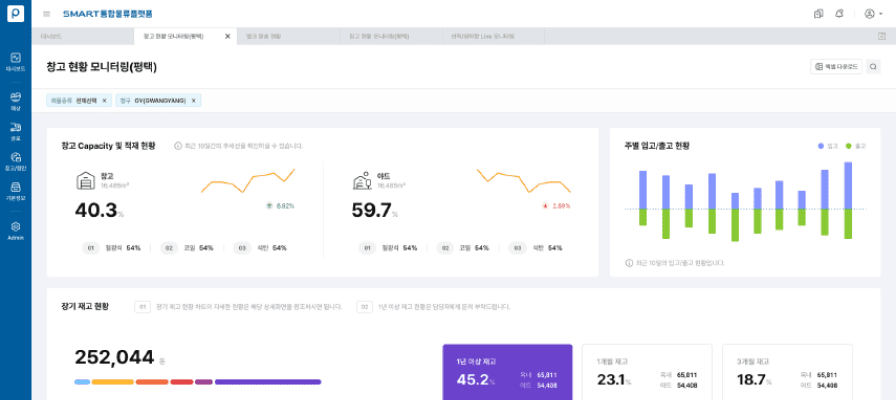

The collected data provides real-time logistics visibility into the location of transportation vehicles, including trucks and ships, which are key control points for logistics operators, as well as the status of orders and inventory, enabling rapid response.

-

Granular monitoring of progress

from order to delivery -

Ship/truck location tracking and

estimated arrival time prediction -

Visibility into inventory

management for directly-managed and non-directly managed*

warehouses* We monitor the warehousing status of non-direct warehouses by implementing virtual WMS through an interface with a warehouse operator.