- HOME

- Solution

- Smart Controller

Smart Controller_PosMaster

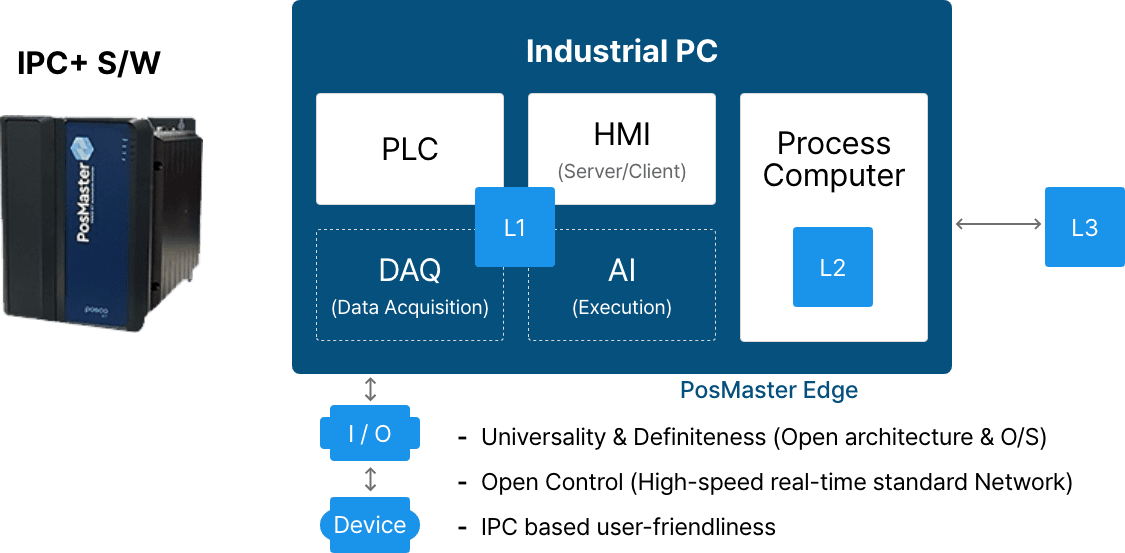

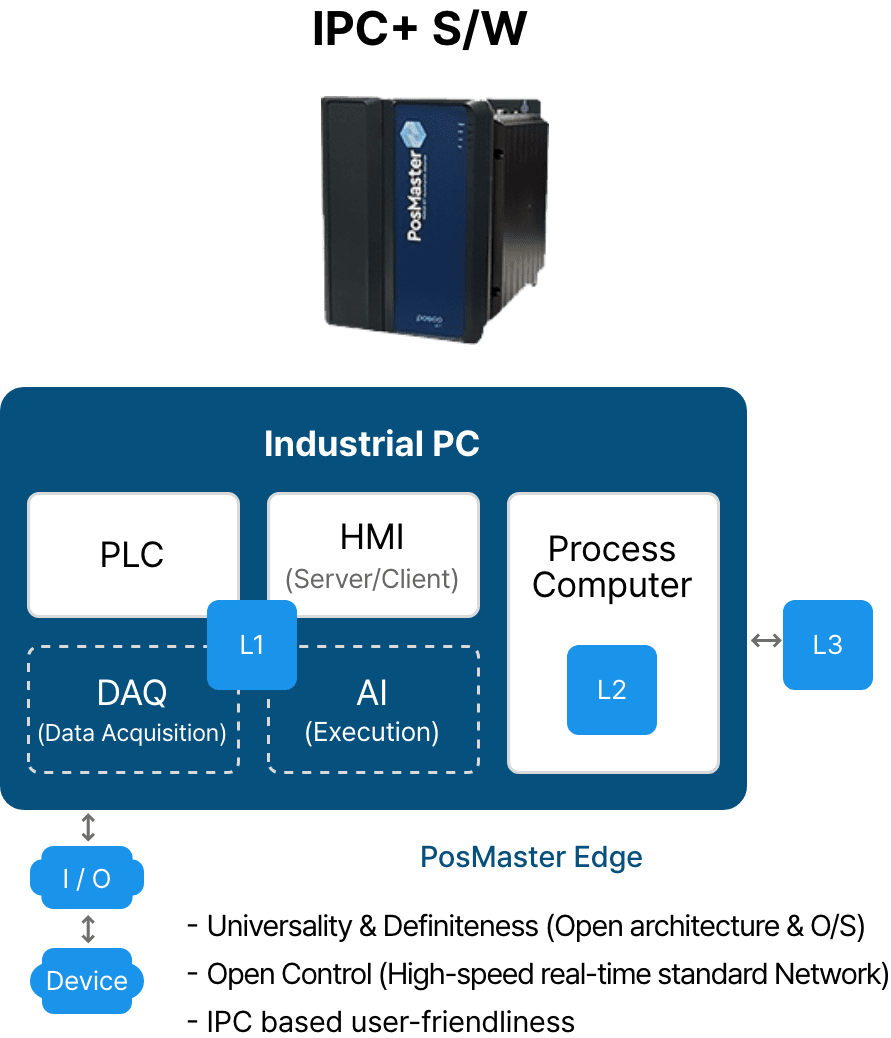

PosMaster was developed with POSCO DX’s unique know-how accumulated through the automation of steel-making and manufacturing processes and digitalization of industrial field systems. It is an IPC-based smart controller that integrates PLC and HMI, which are required by automation systems in the industrial field.

Function

Configuration

PosMaster consists of PosMaster-PLC and PosMaster-HMI and is implemented in modular architecture on the same platform. PLC and HMI of PosMaster process high-capacity I/O data at high speed and support stable system operation with redundancy.

Production and Control System Hierarchy

PosMaster Control System

PosMaster-PLC

Adopted high-performance IPC with a multi-core CPU to support various functions needed for automation and edge computing. Moreover, it can use the same language as the existing PLC by conforming to the international industry standard (IEC61131-3).

- Features

-

- Supports interface to HMI server and L2.

- Supports remote I/O and various Fieldbus communications.

- Implementation of PLC redundancy system. (maximum transfer time of less than 100ms)

PosMaster-HMI

Developed with a proven open source (EPICS), and provides a user-friendly display, API-based functional integration, data acquisition, and trend alarm function.

Features

PosMaster Control System Configuration Examples

Standalone Type

Edge Type