- HOME

- PR

- NEWS

Prev

POSCO ICT fast-tracks its cloud businessNext

POSCO ICT establishes home charging station infrastructure for Hyundai vehiclesPOSCO ICT to disseminate the POSCO smart factory to external customer

2017.09.26

- Installed the smart factory for Donghwa ... Expanding the application scope to manufacturing sites at home and abroad

- Saving- investment costs and securing operation efficiency with the cloud-based system

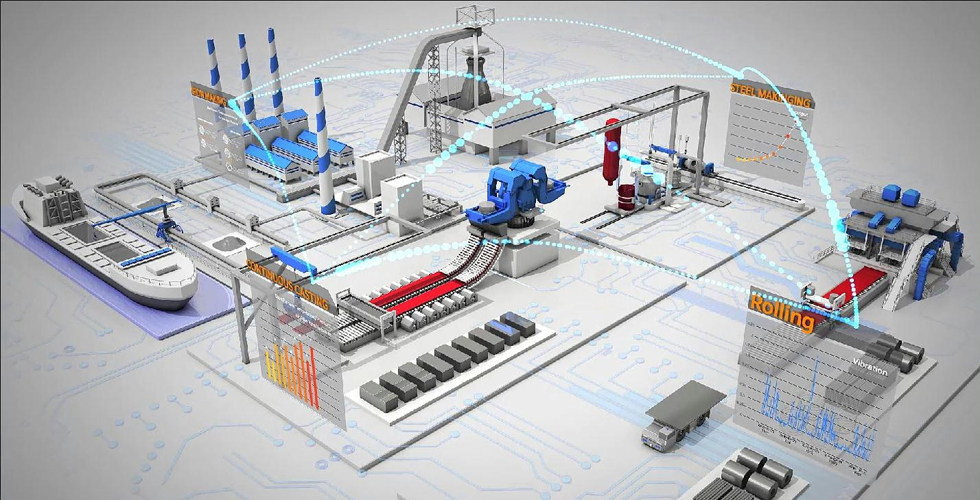

POSCO ICT (CEO Choi, Doo Whan) plans to apply the smart factory installed in POSCO steelworks to other domestic manufacturing sites.

POSCO ICT has announced that it was selected as a service provider of the smart factory construction project for the Donghwa Group (CEO Kim, Hong Jin), the largest wooden materials company in Korea. The Donghwa Group and POSCO ICT have selected the particle board factory as a trial smart factory, and they will implement the project by July next year. The smart factory of the Donghwa Group will be based on the cloud for the first time in Korea; this will reduce the initial construction cost while improving operational efficiency. Besides domestic factories, the Donghwa Group is running their manufacturing factories in 10 countries including Vietnam and Malaysia.

The Donghwa Group is expected to be equipped with a manufacturing environment that collects and monitors equipment and production site data and analyzes big data to control the smart factory optimally using artificial intelligence. For example, the quality level can be enhanced even more by tracking operation conditions in real time through the monitoring of the abnormal symptoms of the facility and by taking actions in advance after checking the factors that can cause defective products. The Donghwa Group expects to reduce defective products by half and unexpected equipment breakdown to less than 1% when such production environment is ready. “Currently, the process is operated based on workers’ experience and intuition. (When the smart factory is in operation), a production environment that manages and operates the factory by analyzing the field data collected by IoT sensors will be implemented,” a Donghwa Group official said.

POSCO ICT has developed PosFrame, the smart industry platform of the POSCO group, and applied it to various industrial sites. The PosFrame platform collects and analyzes the field data and enables optimal control using artificial intelligence, and it is applied to buildings, cities, and energy field besides the smart factory.

“We have implemented the smart factory in the steelworks which requires a continuous process for the first time in the world through cooperation with POSCO. We’re currently trying to spread the smart factory to other sites. Since its effects become tangible after carrying out the project, we’re trying to spread the related system to other manufacturing sites at home and abroad,” a related official from POSCO ICT said.